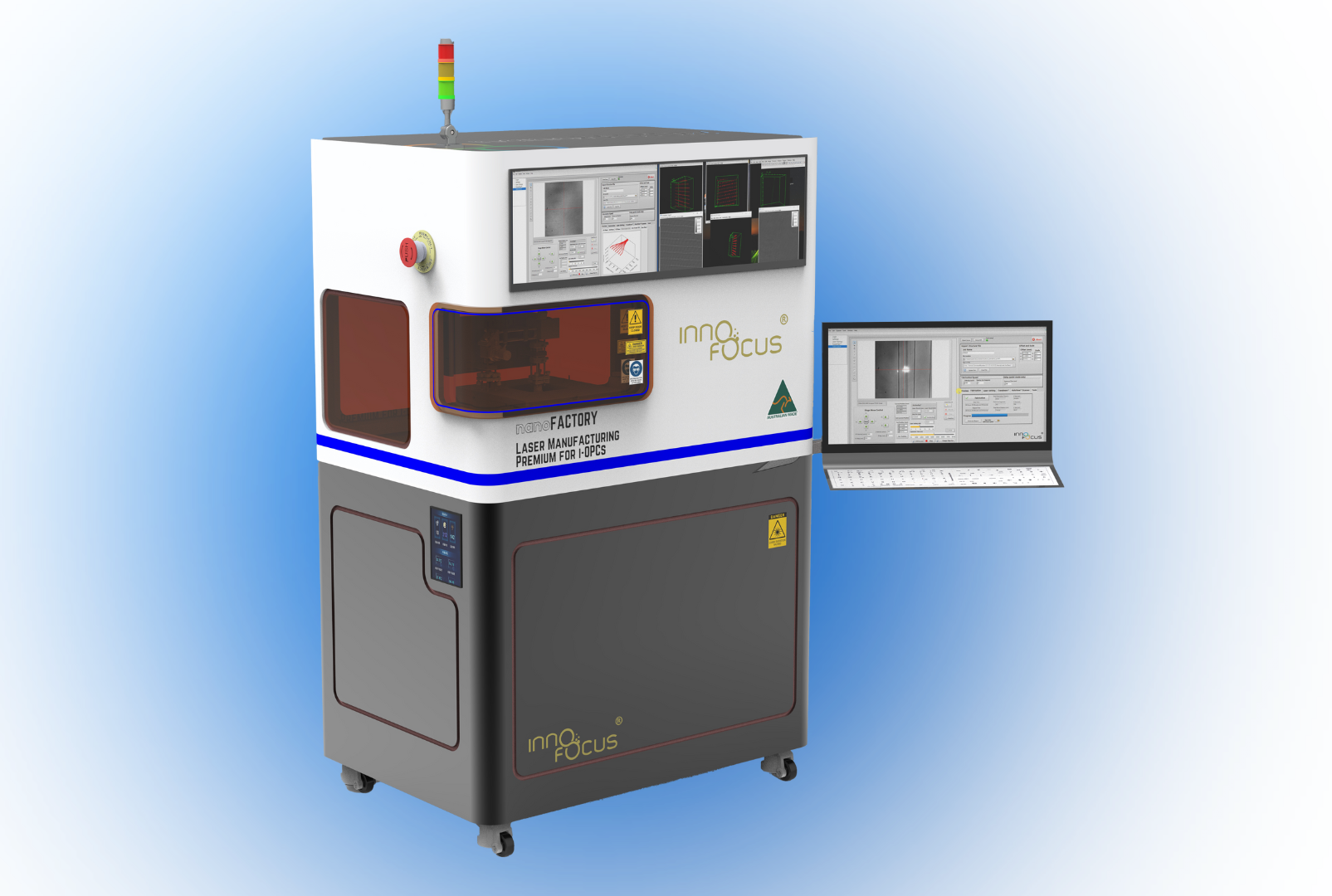

nanoFACTORY i-QPC

A one-stop manufacturing system that meets the needs of industrial-scale nanomanufacturing production lines with high resolution, high efficiency, high accuracy, high device performance and high yield. It can manufacture integrated photonics chips for optical communications, optical sensing, optical computing, and quantum tech.

- Improve exisiting nanoLAB series for the research market.

- Develop nanoFACTORY series for the manufacturing equipment market with high yield, high efficiency, and lower unit cost.

New era with integrated Quantum Photonic Chips

Industry Challenge

The rapid advancement of information technologies in the 21st century has indicated the approaching post-Moore’s law era. Moore’s law, which dictates the doubling of transistors on microchips every two years, has driven traditional computing technology for many years. The demand for higher speed, larger bandwidth, lower energy consumption, and improved security and stability in information technologies continues to grow. However, as we near the physical limits of miniaturisation, new approaches are needed to continue advancing computation.

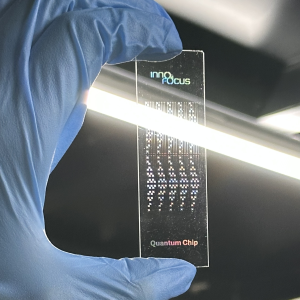

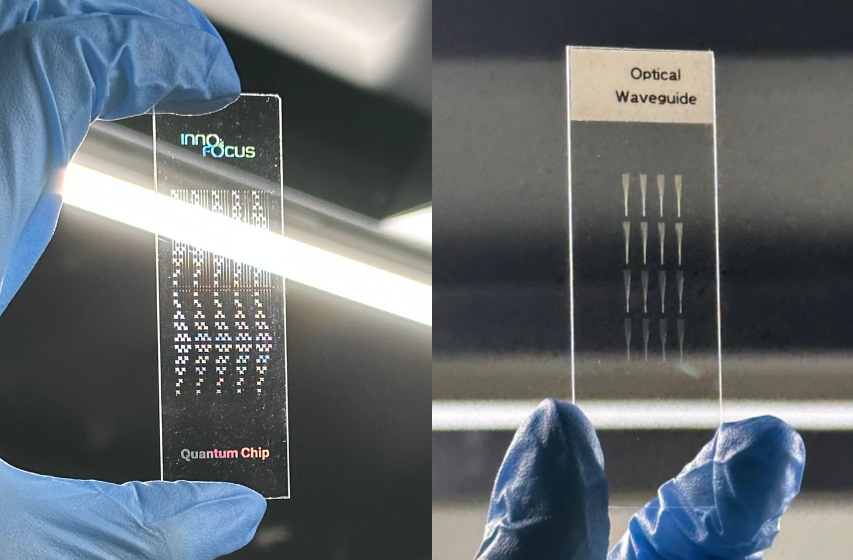

Integrated Quantum Photonic Chips (i-QPC) have emerged as a promising successor to silicon chips. With the continuous development, i-QPCs which offer the desired features including high speed and low power consumption, has become the best solution for high-throughput communication technology. However, as i-QPCs move towards commercialisation and industrialisation, existing fabrication capabilities face significant challenges concerning precision, reproducibility, and scalability to fulfil the needs for R&D and manufacturing.

Conventional configuration of a laser nanofabrication system involves the segregation of distinct modules, with one dedicated to the fabrication process and another intended for characterisation purposes. Therefore, users have to remove the fabricated sample in order to characterise it and then optimise the outcome, leading to a multi-stage and time-consuming process. This hence presents a challenge to the quality control of photonic chips and i-QPC. Additionally, the multi-stage process can introduce error, which results in insufficient correlations between the characterisation results and the fabrication parameters.

To efficiently and accurately characterise nanostructure/nanopatterns of 3D photonic chips has been long sought. However we are yet to find a method that can accurately characterise the refractive index distribution as well as the surface morphology of the optical materials. To fabricate 3D optical structures in optical crystals, the difference in refractive index introduced by laser processing is particularly important, which determines the design of the optical component and its loss.

High Resolution

High resolution

High Efficiency

High Efficiency

High Accuracy

High Accuracy

High Device Performance

High Device Performance

High Yield

High Yield

Product Performance

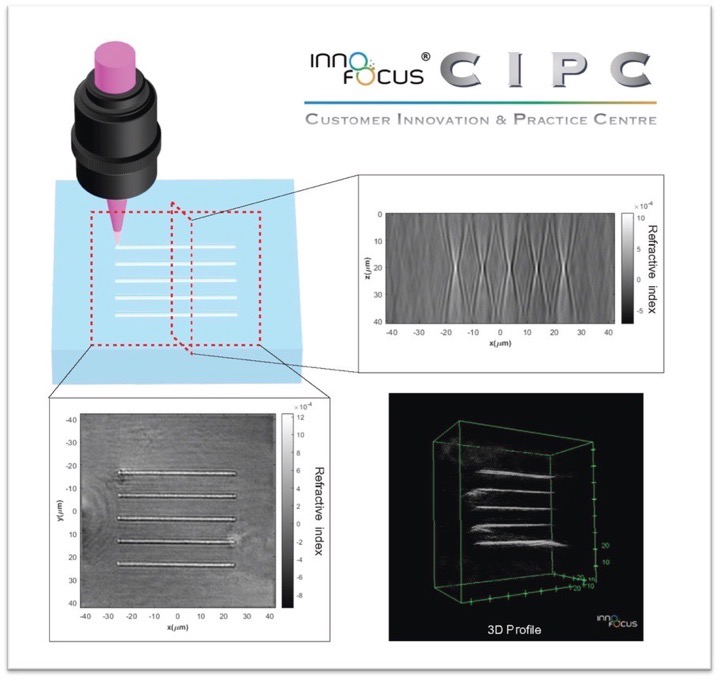

World first laser nanofabrication system with in-situ 3D refractive index imaging functionality

To address these challenges, Innofocus developed the world-first intelligent laser nanofabrication system with our unique in-situ 3D refractive index imaging functionality i.e. HoloView 3DRI. The nanoFACTORY i-QPC model can achieve in-situ refractive index characterisation to help users obtain quantitative data which indicates the variation of refractive index with the parameters changing.

The nanoFACTORY i-QPC model allows on-line inspection of the fabrication outcomes and on-site correction of fabrication conditions, which totally revolutionises the laser nanofabrication sector. It greatly reduces the time span required for the fabrication and characterisation of photonic devices and chips like i-QPCs, meanwhile significantly increasing the laser fabrication accuracy and reproducibility. Users can apply these data to design and simulate the 3D optical waveguide structure to be fabricated, to achieve globally optimal result.

It represents the state-of-the-art and it is the world’s only commercially available high-resolution in-situ 3D refractive index distribution characterisation equipment. Users can now perform characterisation and optimise the fabrication results during the fabrication of sample, which greatly reduces the time cost involved. It enables users to obtain the optimum results in one shot. It provides unprecedented convenience for 3D optical waveguide and photonic chip processing. It provides more support for the industrial applications of laser nanofabrication such as optical communication, all-optical network and quantum optics. The equipment is expected to provide promising solution for the existing industry challenge faced by the development of i-QPCs.

In-situ inspection of the refractive index difference

Quantitative measurement of both the surface and internal refractive index distributions of the components

Determine whether the material has been recharaterised by measuring the changes in its refractive index.

Industry applications